If you work in industrial electrical maintenance, Variable Frequency Drives (VFDs) are everywhere. Pumps, fans, conveyors, mixers—if it spins, there’s a good chance it’s on a drive.

When a VFD faults and the line goes down, the drive is often blamed immediately. Sometimes that’s justified—but more often, the drive is reacting to a problem somewhere else in the system.

This post walks through common VFD fault codes, what they usually mean in the real world, and how I approach troubleshooting before condemning a drive.

The VFD Is a Troubleshooting Tool (Not a Black Box)

A VFD is not a mysterious black box—it’s one of the best diagnostic tools you have.

It gives you:

- Real‑time current data

- Voltage information

- Fault history

- Feedback values

- Load behavior

If a line has been running for weeks or months and suddenly faults, the issue is rarely a parameter change. Start with the fault, the load, and the environment.

Before diving into troubleshooting, take time to familiarize yourself with the drive keypad and available diagnostic screens. A quick glance at the manual often reveals fault details, operating states, and parameters that can save hours of unnecessary guesswork.

Why You Must Check the Drive Manual

Some drives:

- Display only a fault number

- Use the same code for multiple conditions

- Change fault behavior based on parameter settings

Never troubleshoot a VFD fault by name alone.

Two drives from different manufacturers can show the same code and mean completely different things.

Always confirm:

- Fault description

- Trip conditions

- Required reset method

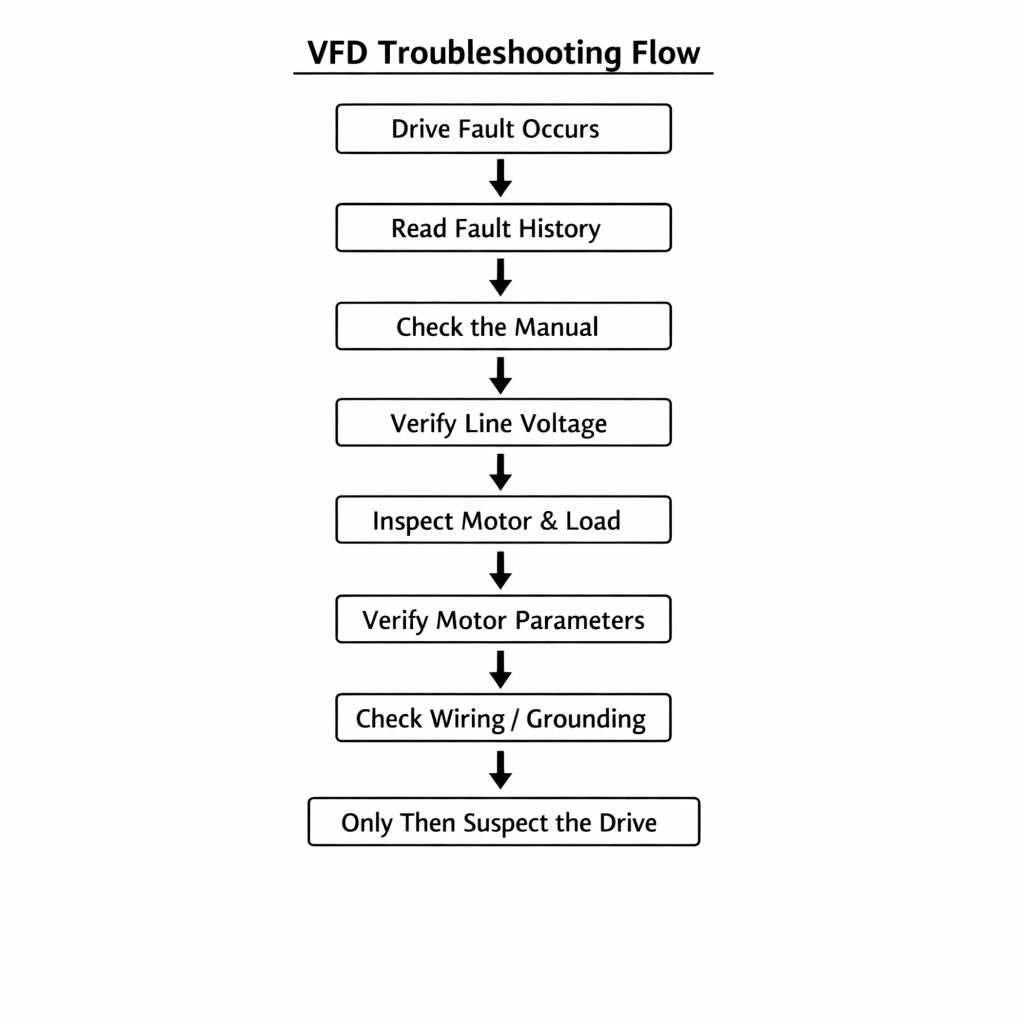

A Simple VFD Troubleshooting Flow

Use this order and you’ll avoid chasing symptoms:

- Read the active fault and fault history

- Look up the fault in the manufacturer’s manual

- Verify incoming line voltage

- Inspect the motor and mechanical load

- Verify parameters vs motor nameplate

- Inspect wiring, grounding, and shielding

- Suspect drive hardware only after everything else checks out

What a VFD Fault Is (and What It Isn’t)

A VFD fault is the drive telling you it detected a condition outside its safe operating limits. It does not automatically mean the drive itself is bad.

VFDs monitor:

- Output current

- DC bus voltage

- Motor feedback (when equipped)

- Temperature

- Communication status

When something doesn’t look right, the drive protects itself—and the motor—by tripping.

Common VFD Fault Codes and What They Usually Mean

Important: Always verify the exact fault description in the manufacturer’s manual.

Many drives only display a fault number, and meanings can vary by brand and firmware.

That said, these are the most common faults I see and what’s typically behind them.

Velocity / Speed Fault

What it usually means:

The drive is being commanded to a speed it cannot achieve.

Common causes:

- Encoder failure or misalignment

- Encoder wiring or shielding issues

- Feedback scaling set incorrectly

- Mechanical load too heavy

- Upstream equipment demanding an unrealistic speed

Field note:

If the line has been running fine and suddenly throws a speed fault, suspect feedback or mechanical load before touching parameters.

Overload Fault

What it usually means:

The motor has been pulling more current than expected for too long.

Common causes:

- Worn or failing bearings

- Jammed or binding equipment

- Process load increase

- Incorrect motor FLA programmed

- Motor cooling issues

Field note:

If the motor frame is hot, the drive is probably telling the truth.

Overcurrent Fault

What it usually means:

Current spiked faster than the drive can tolerate.

Common causes:

- Shorted motor leads

- Ground fault

- Acceleration time too short

- Motor wired incorrectly (delta vs wye)

- Severe mechanical binding

Field note:

If it trips instantly on start, think wiring or parameters—not the drive itself.

DC Bus Overvoltage

What it usually means:

Energy is being pushed back into the drive faster than it can dissipate.

Common causes:

- Deceleration time too aggressive

- High inertia loads

- No braking resistor installed

- Incoming line voltage already high

Field note:

These faults often occur during stopping, not starting.

Ground Fault

What it usually means:

Current is leaking to ground somewhere in the motor circuit.

Common causes:

- Motor insulation breakdown

- Moisture in conduit or motor junction box

- Damaged motor leads

- Improper grounding

Field note:

Disconnect the motor and megger it before condemning the drive.

Communication Fault

What it usually means:

The drive stopped receiving valid commands or data.

Common causes:

- Network cable issues

- PLC fault or program change

- Address conflicts

- Electrical noise on communication lines

Field note:

This is often a controls problem upstream, not a bad drive.

Final Thoughts

Most “bad drives” are victims of:

- Bad motors

- Bad loads

- Bad wiring

- Bad environments

Use the information the drive is giving you.

It’s trying to point you in the right direction.

Leave a comment